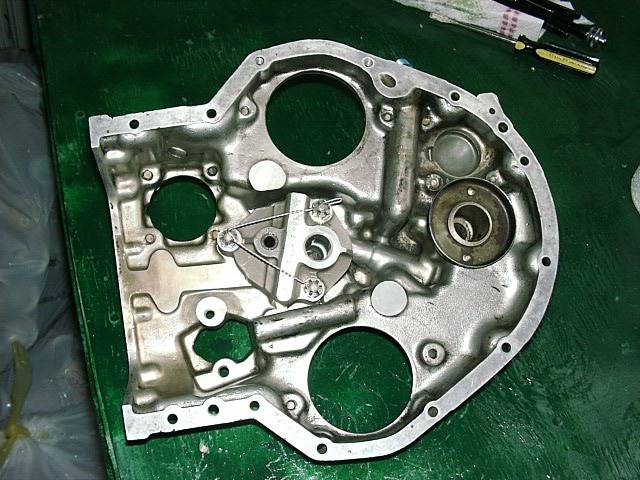

Accessory Case - 11/21/01

There is an AD that states there must be two steel gears in the oil

pump. Unfortunately, you have to remove the Accessory Case to get to

them. The previous owner said he complied and installed a new Superior

pump, but the mechanics wanted serial numbers. So, it gave the the

"opportunity" to check and clean up the accessory case.

| Getting Started |

It's Off! |

|

|

It had a

lot of chipped paint but I decided to leave it bare so I could see any oil leaks

and it would retain its looks a little better.

So here are the damned numbers!! SL 78528 FAA PMA-F

Drilling Oil Journal Drilling Oil Journal

I wish that I had taken a picture of this so its easier to see. There

is a recommendation from Lycoming to drill a hole in the accessory case where

the shaft of one of the oil pump gears fits. The hole is drilled from the

side of the hole to the bottom of it so it lets oil down to the bottom of the

shaft to lubricate it better. I took the accessory case to Lycon in New

Hudson, MI and had it drilled.

Fuel Pump

The Fuel Pump got a bit of cleaning and a little high-temperature engine paint for the housing.

For the record its an AC 93E00A , 41272 FAA PMA. When I first

bought the plane I had a small oil leak when inverted. Turned out to be a

dog-eared gasket on the fuel pump so I was particularly careful reinstalling all

the gaskets.

Tachometer Drive Shaft

The tachometer drive shaft was worn, so I replaced it while things were

apart. After ordering the WRONG one, I discovered I had a 4 bolt camshaft

that required a special part. Didn't want to find a small oil leak caused

by a part that would require me to take the Accessory Case off again! What

I didn't know is that a tiny little 4" shaft (PN 68757) and pin (PN 1199)

76155 would cost

$258.00!!! Oh well. I also replaced the tachometer drive shaft seal

and camshaft bolt retaining clips.

High Pressure Oil Strainer

Constant Speed Prop Governor

Woodward Type 210190 F21080 Model 210305

530426 FAA PMA 514524 S26

Bendix Magnetos

The Magnetos were in good shape so I just captured some numbers while I had

them off. They are Bendix S4LN-21, PN 10-51360-45

| Left |

Right |

| 88631 50483 |

A57320 |

Other New Stuff

Of course while the Accessory Case was off, I replaced all the gaskets,

seals, retaining clips, and the odd sort of item wherever I could.

Reassembly

I was careful not to remove the timing gears, but when I pulled the

tachometer shaft out of the camshaft I knocked all the gears off... So much for

that plan! Anyway, as you can see the timing marks are easy to identify

and line up.

| Accessory Case Back On |

Everybody Back Together |

|

|

Engine mount is wide enough to take the Accessory Case in and out

without any problem. Sump gasket had to be cut so it was just the shape of

the bottom of the Accessory Case and not the full sump. Thin layer of

gasket seal on the Accessory Case, fuel pump, oil screen, and prop governor

gaskets. Bolts torqued to 15 foot pounds.

Mag timing was interesting, I had never done that before. Pretty

straight forward steps:

- Make sure #1 cylinder is on compression stroke

- Set prop on 25 degree mark by taking a straight edge down centerline of engine

- Open inspection covers on mags and find the "red" tooth

- Center red tooth even with timing mark on case

- Insert (carefully) mag into Accessory Case

- Disconnect cables and insert timing light leads (right=red, left=green,

ground=black)

- Barely rotate one mag until exact moment light goes on or off

- Rotate other mag the same way

- Move prop checking to make sure right and left light/disappear at the same time

(back prop up enough to take slack out of gears, then forward to check)

- Adjust mags as necessary to produce desired result

Bonus!! No Leaks!

45GG started right up and after holding my breath for a few seconds the oil

pressure popped up to a very nice level. I let it run for a while and get

warm before I shut it off and checked to see if there were any leaks.

There weren't any so I buttoned it up and did a couple of high-speed taxis down

the runway. Still no leaks, so we went for a ride. Man, did it feel

good to get back in the air again. It only took me an hour and change to

take everything apart... about four to put everything back. But the

problem was waiting on the tachometer shaft. I ordered it the day before

Thanksgiving and called to check the following Tuesday. They forgot to

order it!! So it ended being out of action a little over a week.

11/29/01

|